Hello, believe that guys engaged in structured cabling know the three core components of copper system: Keystone jack, Patch cord and LAN cable. They are the core products to ensure the last 100mtr link of the cabling system. Only by controlling the quality of these three products can any cabling system project ensure the transmission quality of the network system.

Today, Copperled shall share with you how to distinguish the quality of one of the components "Keystone jack".

About Keystone Jack

According to standard YD/T926 3, "Keystone jack" is called "keystone socket", which belongs to one of the products of "connection hardware" of cabling system; According to ANSI / TIA-568, it belongs to "RJ45 Jack" in "connecting hardware".

Of course, according to other different standards and specifications, it has different names, such as "computer module", "network module" and so on. For your convenience, we commonly call it "keystone jack".

With the continuous development of network information, more and more keystone jacks are used, and the requirements of network speed are also increasing, so the keystone jack becomes more and more important. However, with the increasing dosage, the quality of products is more mixed.

After all, the keystone jack is an industrial product. Although there are methods to distinguish the quality, as ordinary users, it is often difficult to really judge the quality of the keystone jack without professional instruments.

Today, from the perspective of users, Copperled shares with you to judge the quality of a module from the nuances of appearance, structure and performance.

At present, the commonly used keystone jacks include Cat5e, Cat6, Cat6A and Cat.8. The modules are generally engraved, as shown in the pictures below:

There are two types of keystone jack: Unshielded and Shielded.

Unshielded keystone jack good modules generally use polycarbonate material (Engineering PC material). This kind of product will be better in repeated construction and the elasticity and plasticity of the installation buckle. Some products are made of ordinary engineering ABS materials. The quality of these products will be slightly worse, but we must pay attention to the modules produced with recycled plastic materials. The repeated construction of those products is very poor, and the buckle position is extremely easy to break. They are inferior modules. When identifying, we can try the elasticity of the snap position of the module by hand. If the elasticity is poor and easy to break, it is a very poor product;

Secondly, look at the appearance and whether the workmanship is fine. If the surface is not smooth, the mold trace line is obvious, the edge and corner treatment is not round, and the surface has burrs, it indicates that the mold used in the production keystone jack is poor, the production process is poor, and the material is poor.

Shielding keystone jack: two materials are generally used for external structural parts: tinned copper sheet and zinc alloy die-casting and then electroplating. As shown below:

In terms of the full shielding performance, structural reliability and service life of the product, the shielding modules plated after zinc alloy die-casting are better than the shielding modules of tin-plated copper shell, and the tin-plated copper shell shielding structure is no longer used in high-level shielding keystone jacks (such as class 6a and class 8), because the full shielding effect can not be achieved at all. At present, there are still tinned copper shielding keystone jacks on the market. In case of such products, we should carefully distinguish them. Generally, the quality of such modules is poor. In addition to these two types, special attention should be paid to: there are shielding modules using stainless steel as shielding shell, which are of poor quality;

For the shielding keystone jack of zinc alloy shell , it should also be noted during identification. Since the quality of zinc alloy shell depends on the die-casting die, production process, zinc alloy raw materials and electroplating process of the manufactured products, special attention should be paid to the products with good surface quality, smooth and burr-free and uniform electroplating. Otherwise, the quality is relatively poor.

First of all, let's take a look at the 8pin gold pin inside the socket of the keystone jack. This is a very key part related to transmission performance.

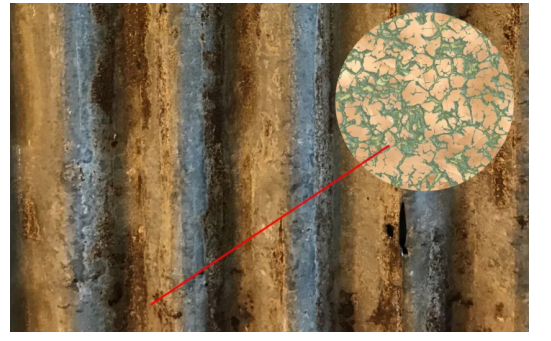

A: Visually observe whether the gold pin is smooth and burr free. The surface of the gold pin of the keystone jack is electroplated with gold after nickel plating, and the transmission contact area is plated with 50U "gold. If the plating quality is poor, the thickness of the nickel bottom is not enough, the thickness of gold plating is not enough, gold plating floats, and some even copper plating instead of gold plating, such gold pins cannot pass the plug-in test and salt spray test, and the product surface will be dark, burr, or even halogen (green on the surface). The product quality must be very poor, which will affect the transmission performance.

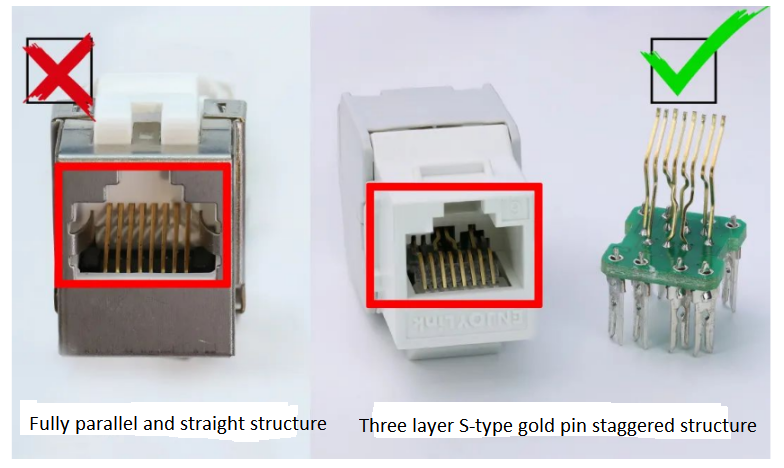

B: Look at the structure of 8pin gold pin. Now, with the continuous development of the network, the structure of the golden pin is also constantly improving. Especially the continuous application of POE technology, the gold pin structure has been applied from the previous fully parallel and straight structure to three layer S-type gold pin staggered structure. As shown below:

Fully parallel and straight structure: the friction point and the fixed contact point are the same point during plugging, which will affect the performance of POE; And the fully parallel and flat structure gold pins are not separated and staggered, which will cause mutual interference during signal transmission and is not conducive to the stability of link transmission.

Three layer S-type gold wire staggered structure: the friction point and the fixed contact point are not the same point when plugging in and out, so as to meet the performance of Poe; And the three-layer S-type gold pin interleaving structure can well reduce the interference between line to transmission and improve the link stability.

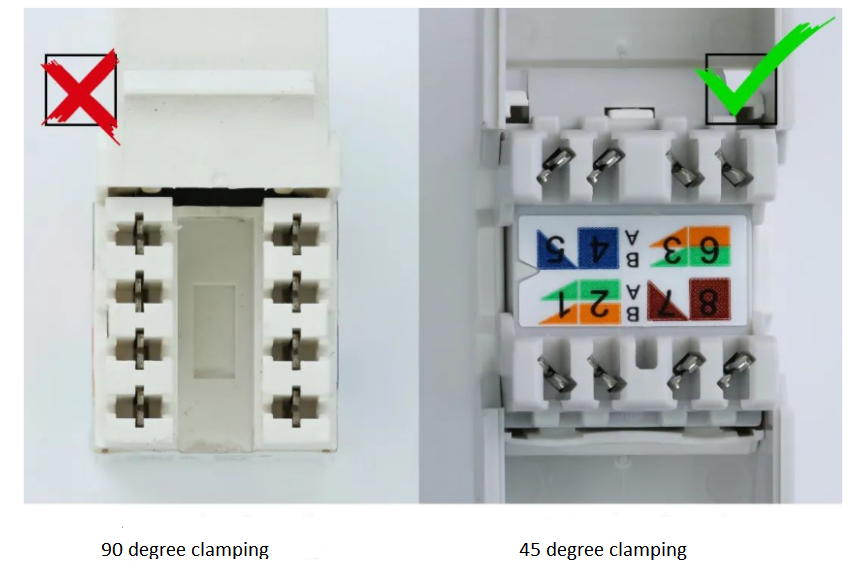

Secondly, look at the conductor 8pin card line terminal at the tail of the keystone jack, which will directly affect the cable termination quality of the module. Modules with good quality are generally clamped with 45 degree inclined terminal structure, but some modules with lower end still use 90 degree clamped terminals. As shown below:

90 degree clamping: the performance of repeated construction is poor, and if the clamped cable of 90 degree clamping terminal is too thick, the cable may be broken. If the cable is too thin, it is stuck on the surface, but the core wire is not pierced, which will lead to poor contact;

45 degree clamping: the performance of repeated construction is good, and no matter what wire gauge the cable is, it can ensure that the cable will not be broken and the continuity of the cable.

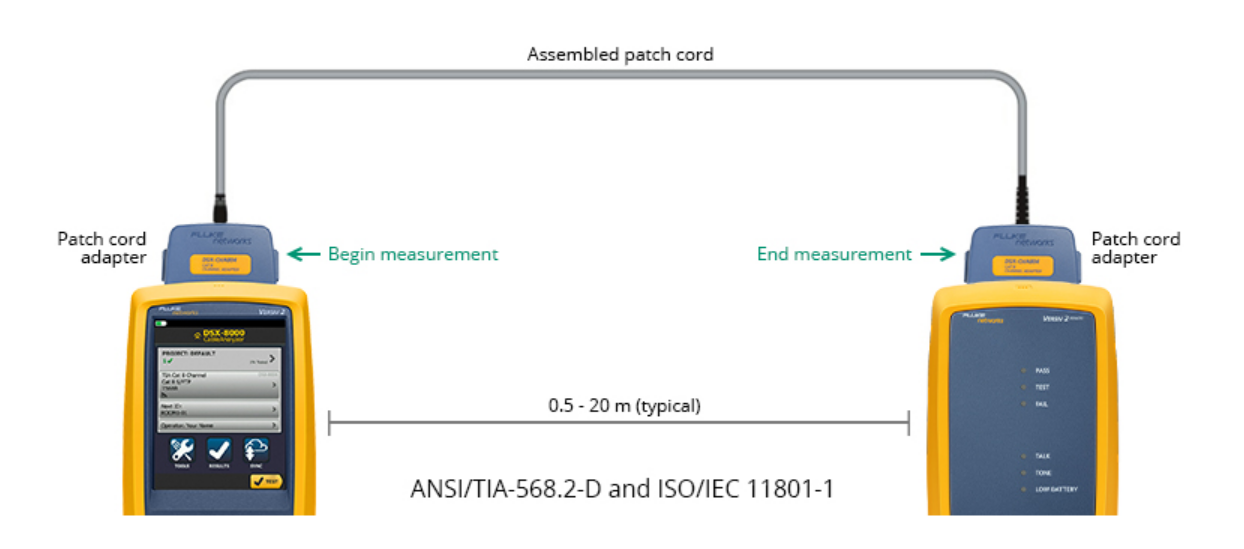

For industrial products such as keystone jacks, they have to be tested many times, and by very professional equipment. It is difficult for ordinary users to have these equipment. Here, Copperled recommends a method to identify the transmission performance of the keystone jack. We all know that there will be a performance test of permanent link before the selection of cabling system. First, we need to determine a qualified network cable, make a 10m short link and a 90m standard link respectively according to the permanent link model, and then test with fluke engineering test instrument. If the test results are all qualified, it means that this keystone jack is qualified. And a good module can compensate the whole link.

The quality of the keystone jack is related to the speed of network transmission, so we must use good modules. Shenzhen Copperled Technology Co., Ltd. is your better choice. Finally, we summarize that a good module have the following characteristics:

1. Gold plating thickness reaches 50μ;

2. Three-layer S-shaped gold pin staggered structure;

3. The shielding module shall adopt zinc alloy integral die-casting shell;

4. Clamp the terminal at an angle of 45 degrees;

5. Fluke short link and 90m permanent link passed the test.

The above is how Copperled shares with you to distinguish the quality of keystone jacks. Have you learned it? Any query or support you need, please feel free to contact us by email:

sales@copperled.com or WhatsApp +86 13427942867.

Thanks &Best Regards,

International Marketing Dept.

Shenzhen Copperled Technology Co., Ltd.