Hello, dear all.

Last time, we have shared with you how to make a patch cord yourself. Today, I would like to show you the production procedure in the patch cord factory. Let's follow me to the production line.

1. Cables testing

2. Peel off the cable jacket

3. Ready for rubbing:

A. For Cat.5: process step 4 directly

B. For Cat.6: Prepare the plastic crossing first

C. For FTP cables: Remove the foil shield, and prepare the crossing

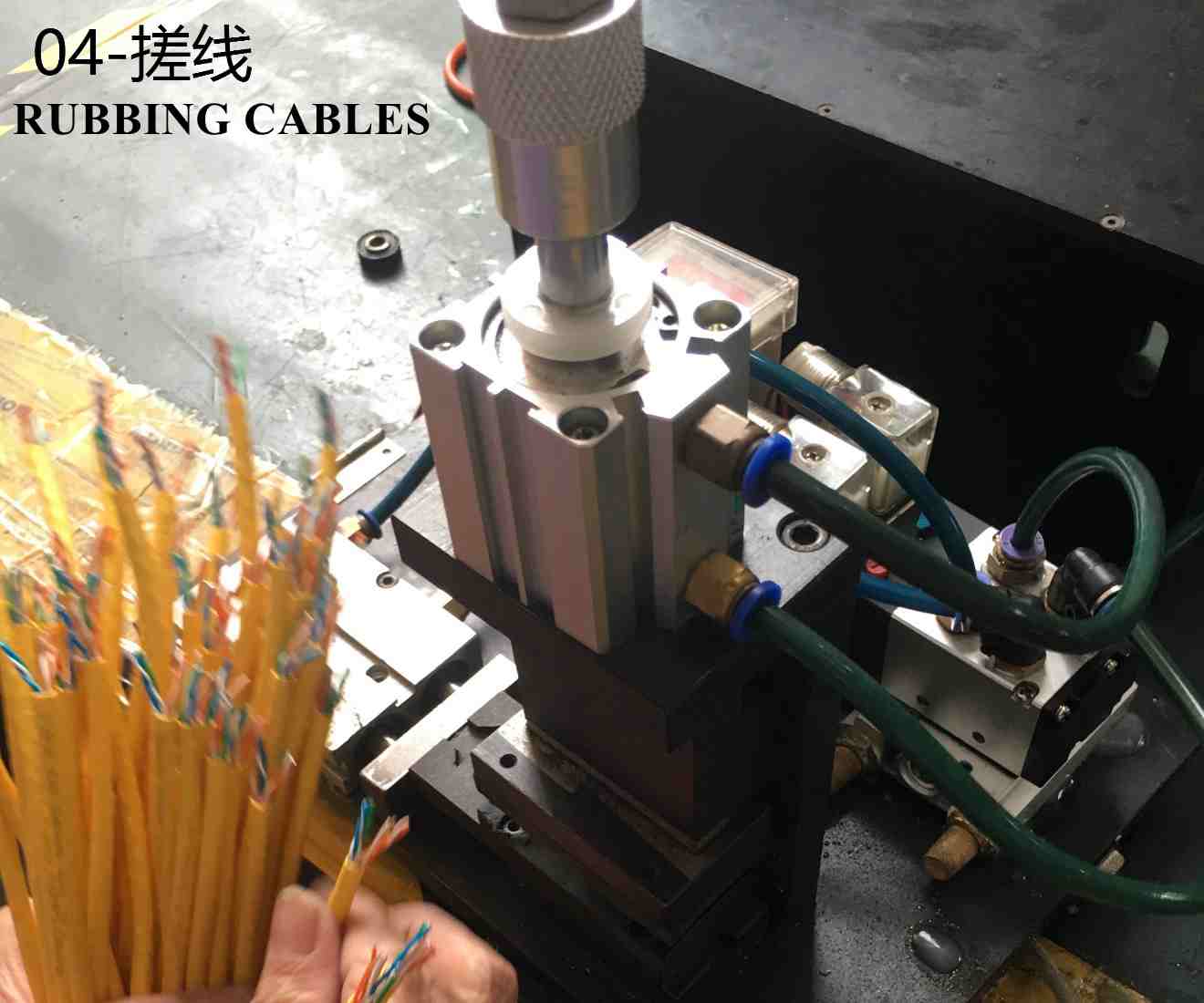

4. Rubbing cables

5. Assembly into the connector(plug)

A: strip back the cable jacket (5-10mm for reference)

B: Use the 568-B wiring scheme for a standard patch cable.

C: The patch cord performance and looking are related to the connector.

D: Different testing will use a different plug.

(Channel test: simply one-piece type connect)

(Link test: Normally will be two or three pieces type connector.)

E: Connector type: separated in long body and short body, short body especially use in 90 degrees bending needed.

6. Squeezed the cables and connector together

7. Injection molding

The pressure of the injection should be adjusted fine, cannot be too low or too high, if the pressure is too low, the injection will be uneven, if too high, will make the connector cracked.

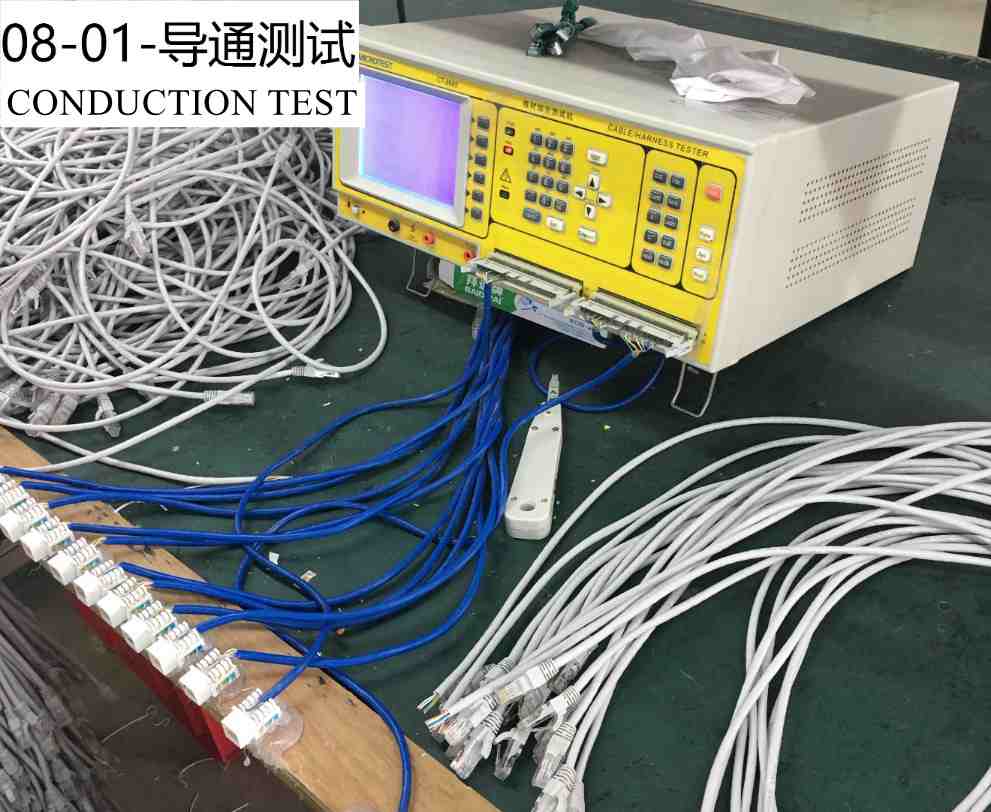

8.Testing:

A.Conduction test: 100% test. Mainly to test if the cables were conducted. The rate of a defective product will be controlled between 0.5-1%, and the cause will be analyzed then back to step2.

B. Permanent link test: Sampling detection

a. test the cables with the modular, test tool: FLUKE, connector: DTX-PLA002

b. then test the patch cord, test tool: FLUKE, connector: DTX-CHA002

c. keep distance between each cable to avoid interference

d. Normally the cables need to pass the 90M Permanent link test

C.Channel Test, Test tool: FLUKE, connector: DTX-CHA002

D. Patch Cord Test, Test tool: FLUKE

(Patch cord can pass the test will surely pass the channel test)

9.Winding the Patch cord.

10. Packing and ship

Sealing, tagging pack into a carton.